INTRODUCTION TO AUTOMATION SYSTEMS

In an agriculture the most of the operations are performed manually & which requires lot of attention & care. It is difficult to perform the agriculture activities effectively & precisely under the human control. Ultimately thisn may result in low crop production, non uniform growth of crop & poor quality of fruits or grain. Smartflo provides automation solution to overcome the problems, improves the quality & yeild of crops. We have the complete range of automation systems & solutions for agriculture, protected cultivation technolgy, nurseries, vertical gardening, landscaping, lift irrigation projects & community based irrigation solutions.

WHAT IS AUTOMATION & WHY IT IS IMPORTANT IN AGRICULTURE?

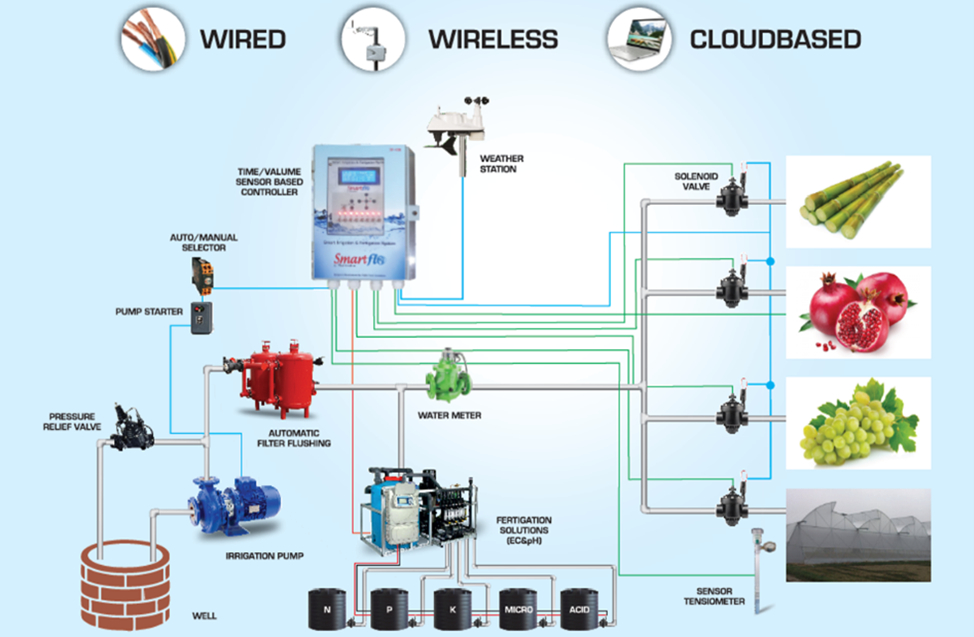

Automation of an Irrigation & Fertigation system helps to minimize the human efforts & errors to improve the crop yield with quality & quantity. Introduction of Automation system in an agriculture / Irrigation Sector have positive effect on application efficiency, reduction in labour cost, fertigation efficiency, water & energy saving, operational feasibility, peace of mind etc. Automation of an irrigation system refers to operation & maintenance of irrigation system with minimum manual intervention required for programming / scheduling as per the design & requirement of specific crop in open field or greenhouse.

ADVANTAGES OF AUTOMATION SYSTEM:

- Optimum utilization water as it performs the operations on the basis of time, volume & sensor.

- Precise application & operation of dissolved fertilizers on continuous, proportional, EC & pH sensor based.

- Ease of Operation & flexibility to control the operation through controller screen, computer, laptop & smart phone.

- Increased efficiency of water and fertilizer use both in controlled environment & open field application.

- Systems can be operated 24 x 7 for 365dya as per the electricity availability.

- Savings in energy cost and water.

- Automated Irrigation management system provides an access to Owner & Technician. i.e. Developer, Manager & Technician access to system.

SCOPE OF AUTOMATION SYSTEMS:

- Irrigation pump operation i.e. single pumping unit to multiple

- Automatic operation of irrigation system (Time, Volume & Sensor basis)

- Operation of misting & fogging system (Time, Volume & Sensor basis)

- Operation of green house system (Time, Volume & Sensor basis)

- Operation of fertigation system i.e. dosing pump, EC & pH monitoring system

- Filter cleaning or flushing on time & pressure differential basis.

- Automated weather monitoring system operation e.g. wind speed, direction, sunshine hours or radiation, temperature, humidity, electrical conductivity etc.

- Alarm & alerts for malfunctioning operations through SMS or reports, e.g. power failure, high & low pressure alerts, pipeline bursting, high & low temperature & humidity alerts etc.

- Community based / lift irrigation systems operations by assigning the certain authorities to each level. e.g. Owner, Manager, Technician access to irrigation & fertigation system.

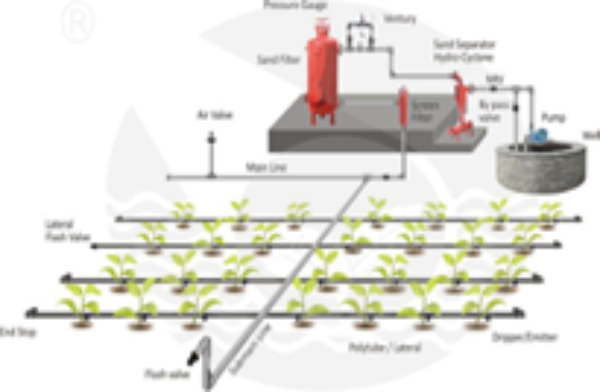

SCHEMATIC LAYOUT OF AUTOMATION SYSTEMS

COMPONENTS OF AUTOMATION SYSTEMS:

SMARTFLO CONTROLLER:

It is designed to operate the irrigation & fertigation system on the basis of Time, Volume & Sensor.

Valve Operations: 1 to 256 Valves (Wireless model upto 1000 valves)

Fertigation Machine: 02 for standard models & 10 for expandable models

Sensors: 6 to 32 (Analog & digital)

Pump Operations: 02 for standard Models & 10 pumps for expandable Models

Controller Programming Access: Control Panel, GSM Based, Laptop / Computer or through (Internet / Ethernet / Intranet).

MODELS:

SMARTFLO – 4 CHANNEL MODEL:

- “Time” based control system

- Total Valves Operations (ON/OFF): 04 Nos

- Irrigation Pump Operation (ON/OFF): 01 Nos

- Fertigation Pump Operation (ON/OFF): 01 Nos

- Irrigation & Fertigation Programming: Weekly

- Irrigation & Fertigation Programming: Cyclic (3 cycles per day)

- Electrical Protection: High & low voltage cut-off

- Electrical Protection: Dry-run protection

- LED indicators -Three phase, Motor & Controller Status

- Capacity of controller: Single / Three phase motors, 0.5 to 25 HP

SMARTFLO – 8 CHANNEL MODEL:

- “Time & Volume” based control system

- Green house & Open field operation

- Total Valves Operations (ON/OFF): 08 Nos

- Irrigation Pump Operation (ON/OFF): 02 Nos

- Filtration Unit Flushing (ON/OFF): 02

- Fertigation Pump Operation (ON/OFF): 02 Nos (up to 05 Tank)

- Irrigation & Fertigation Programming: Weekly

- Irrigation & Fertigation Programming: Cyclic

- Electrical Protection: High & low voltage cut-off

- LED indicators – Motor, Valve & Controller Status

- Capacity of controller: It can sync DOL & Star Delta

- Communication (GSM Operation)– SMS & Mobile Application

SMARTFLO – 8 CHANNEL MODEL:

- “Time, Volume & Sensor” based control system

- Green house & Open field operation

- Total Valves Operations (ON/OFF): 08 Nos

- Irrigation Pump Operation (ON/OFF): 02 Nos

- Filtration Unit Flushing (ON/OFF): 02

- Fertigation Pump Operation (ON/OFF): 02 Nos (up to 05 Tank)

- Irrigation & Fertigation Programming: Weekly

- Irrigation & Fertigation Programming: Cyclic

- Electrical Protection: High & low voltage cut-off

- LED indicators – Motor, Valve & Controller Status

- Capacity of controller: It can sync DOL & Star Delta

- Communication (GSM Operation)– SMS & Mobile Application

- Sensor Operations: 06 Nos

SMARTFLO – 16 CHANNEL MODEL:

- Time & Volume” based control system

- Green house & Open field operation

- Total Valves Operations (ON/OFF): 16 Nos

- Irrigation Pump Operation (ON/OFF): 02 Nos

- Filtration Unit Flushing (ON/OFF): 02

- Fertigation Pump Operation (ON/OFF): 02 Nos (up to 05 Tank)

- Irrigation & Fertigation Programming: Weekly

- Irrigation & Fertigation Programming: Cyclic

- Electrical Protection: High & low voltage cut-off

- LED indicators – Motor, Valve & Controller Status

- Capacity of controller: It can sync DOL & Star Delta